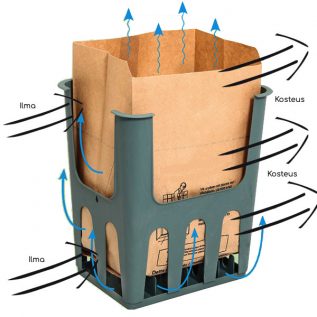

Hengittävä järjestelmä hajottaa biojätteen aerobisesti eli jäte kuivuu mädäntymisen sijaan. Menetelmä vähentää pahoja hajuja ja esimerkiksi kärpäsiä.

Hengittävä järjestelmä perustuu ilmanvaihtoon. Se edesauttaa nesteen haihtumista jätteestä, mikä vähentää pahasta hajusta ja kärpäsistä syntyviä ongelmia. Jäte on myös kevyempää kuljettaa, eikä se jäädy kiinni ulkona olevaan jäteastiaan. Jäte kuljetetaan biokaasulaitokseen. Kun ilmanvaihto toimii koko ketjussa, tulos on paras mahdollinen.

Paperisäkin käyttö ilmavassa roska-astiassa pitää astian puhtaana ja raikkaana. Paperisäkillä on erityinen kyky varastoida biojätteen kosteutta ja haihduttaa sitä pois. Vettähylkivästä märkälujapaperista valmistettu pussi sopii hengittävään järjestelmään, sillä se päästää lävitseen vesihöyryä muttei vesipisaroita. Pussilla on eurooppalaisen standardin EN 13432:n mukainen hyväksyntä.

Paperipussi on hiilineutraali

Hiilineutraali paperipussi on ympäristöteko muunlaisiin pusseihin verrattuna. Muovipussit tuottavat hiilidioksidia, biomuovipussit puolestaan aiheuttavat happamoitumista ja rehevöitymistä. Paperipussi sopii hyvin lajitteluun ja se pystyy keräämään eniten jätettä.

Käytä aina ilmavaa 8L biojäteastiaa, sillä suljetussa astiassa pussi ei saa tarvitsemaansa ilmaa ja vuotoriski on mahdollinen.

Hengittävä järjestelmä

Hengittävä järjestelmä Paperipussi

Paperipussi Teline

Teline Sulkeminen

Sulkeminen WR-paperi

WR-paperi Kohokuvioitu pinta

Kohokuvioitu pinta Tulokset

Tulokset